Briggs & Stratton 250000 manuels

Manuels d'utilisation et guides de l'utilisateur pour Accessoires et composants de véhicules automobiles Briggs & Stratton 250000.

Nous fournissons des manuels en pdf 2 Briggs & Stratton 250000 à télécharger gratuitement par type de document : Spécifications, Manuel du propriétaire

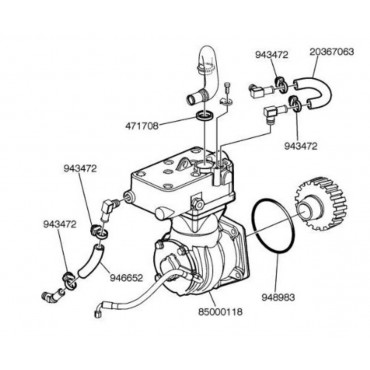

Briggs stratton 250000 Spécifications (338 pages)

marque: Briggs-stratton | Catégorie: Accessoires et composants de véhicules automobiles | Taille: 10.45 MB |

Table des matières

8

11

13

18

19

21

23

23

31

31

39

39

60

60

63

71

71

72

78

78

80

80

80

80

81

82

83

84

84

84

85

85

90

97

98

100

102

109

109

113

119

119

119

125

126

127

127

128

130

133

133

133

133

136

137

137

137

138

138

138

141

141

149

152

160

164

165

166

166

171

171

172

172

172

173

173

180

189

189

192

192

193

196

199

199

200

200

204

209

213

214

215

215

219

219

228

231

235

238

241

242

246

251

251

252

253

258

263

266

267

269

275

275

277

279

279

280

283

291

294

294

295

297

298

304

311

312

315

315

319

320

320

321

324

327

330

333

334

334

337

338

Briggs stratton 250000 Manuel du propriétaire (20 pages)

marque: Briggs-stratton | Catégorie: Accessoires et composants de véhicules automobiles | Taille: 0.82 MB |

Table des matières

11

14

Plus de produits et de manuels pour Accessoires et composants de véhicules automobiles Briggs & Stratton

| Modèles | Type de document |

|---|---|

| 460000 |

Manuel du propriétaire

Briggs & Stratton 460000 Owner`s manual [en] ,

20 pages

Briggs & Stratton 460000 Owner`s manual [en] ,

20 pages

|

| 470000 |

Spécifications

Briggs & Stratton 470000 Specifications,

57 pages

Briggs & Stratton 470000 Specifications,

57 pages

|

| 589447 |

Instructions d'exploitation

Briggs & Stratton 589447 Operating instructions,

20 pages

Briggs & Stratton 589447 Operating instructions,

20 pages

|

| PROFESSIONAL SERIES 140000 |

Manuel de l'opérateur

Briggs & Stratton PROFESSIONAL SERIES 140000 Operator`s manual [en] ,

28 pages

Briggs & Stratton PROFESSIONAL SERIES 140000 Operator`s manual [en] ,

28 pages

|

| 120000 Quantum 625 Series |

Manuel d'utilisateur

Kullanma Kılavuz [en] ,

12 pages

Kullanma Kılavuz [en] ,

12 pages

|

| 134200 |

Manuel d'utilisateur

Operator/Owner Manual Korisnički priručnik Příručka [en] ,

57 pages

Operator/Owner Manual Korisnički priručnik Příručka [en] ,

57 pages

|

| 09A400 |

Manuel d'utilisateur

Illustrated Parts List,

12 pages

Illustrated Parts List,

12 pages

|

| Sprint 90000 |

Manuel d'utilisateur

Classic /Sprint /Quattro Model Series 90000, 100000,

10 pages

Classic /Sprint /Quattro Model Series 90000, 100000,

10 pages

|

| 290700 |

Manuel d'utilisateur

Briggs & Stratton 290700 User's Manual,

20 pages

Briggs & Stratton 290700 User's Manual,

20 pages

|

| Snow Blower 120000 |

Manuel d'utilisateur

Briggs & Stratton Snow Blower 120000 User's Manual,

28 pages

Briggs & Stratton Snow Blower 120000 User's Manual,

28 pages

|

| VANGUARD 290000 |

Manuel d'utilisateur

Briggs & Stratton VANGUARD 290000 User's Manual,

92 pages

Briggs & Stratton VANGUARD 290000 User's Manual,

92 pages

|

| Outboard Motor 800 |

Manuel d'utilisateur

Briggs & Stratton Outboard Motor 800 User's Manual,

112 pages

Briggs & Stratton Outboard Motor 800 User's Manual,

112 pages

|

| 90000/10000 |

Manuel d'utilisateur

Briggs & Stratton 90000/10000 User's Manual,

20 pages

Briggs & Stratton 90000/10000 User's Manual,

20 pages

|

| 194700 |

Manuel d'utilisateur

Briggs & Stratton 194700 User's Manual,

20 pages

Briggs & Stratton 194700 User's Manual,

20 pages

|

| 12K300 |

Manuel d'utilisateur

Briggs & Stratton 12K300 User's Manual,

16 pages

Briggs & Stratton 12K300 User's Manual,

16 pages

|

| 190000 |

Manuel d'utilisateur

Briggs & Stratton 190000 User's Manual,

20 pages

Briggs & Stratton 190000 User's Manual,

20 pages

|

| Digital Camera 133200 |

Manuel d'utilisateur

Briggs & Stratton Digital Camera 133200 User's Manual,

76 pages

Briggs & Stratton Digital Camera 133200 User's Manual,

76 pages

|

| VANGUARD 300000 |

Manuel d'utilisateur

Briggs & Stratton VANGUARD 300000 User's Manual,

20 pages

Briggs & Stratton VANGUARD 300000 User's Manual,

20 pages

|

| 407700 |

Manuel d'utilisateur

Briggs & Stratton 407700 User's Manual,

20 pages

Briggs & Stratton 407700 User's Manual,

20 pages

|

| VANGUARD 540000 |

Manuel d'utilisateur

Briggs & Stratton VANGUARD 540000 User's Manual,

20 pages

Briggs & Stratton VANGUARD 540000 User's Manual,

20 pages

|

Briggs & Stratton appareils